Deutsche Fassung

Deutsche Fassung

SIMONA as a partner

- Close collaboration on project detailing with the end customer/processing contractor

- Technical support as early as the planning phase

- Development of a planning proposal by SIMONA

- Welding instruction and supervision on site

.

SIMONA® piping systems for the rehabilitation of a waste-water pump pipeline

A cast-iron pipeline had been eroded by constant discharge of solids; after roughly 38 years of operation pipe fractures had appeared at several points. Extensive pipe rehabilitation had thus become an urgent necessity. In this project it was particularly important for the new waste-water pressure pipes to have a highly wear-resistant inner layer.

Based on PAS1075 types 2 and 3, SIMONA® PE 100 RC AP-Line CoEx waste-water pressure pipes are manufactured without and with a protective jacket, respectively. They are particularly suitable for meeting the requirements of this project. Owing to a high level of notch and crack resistance, it was possible to lay the new pressure pipeline by the trench-cutting method. This not only saved time, it is also cost-effective.

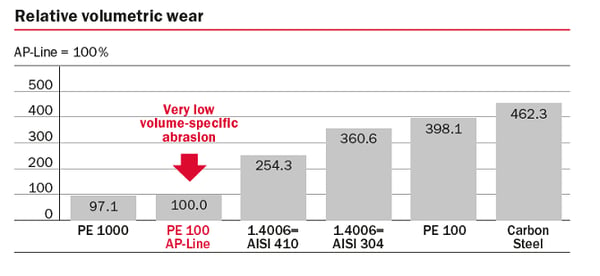

The product group SIMONA® AP Line is characterised by an AP-Line inner layer that is extremely abrasion-resistant. Compared with PE 1000, the self-developed AP formula has a comparatively low level of volume wear in the sand-slurry test and approx. 75% less abrasion than PE 100.

The system provider supplemented the project with appropriate fittings such as bends with r = 5d, as well as custom components such as loose flanges and F-pieces.

The SIMONA® AP-Line product range for waste-water pressure pipelines offers significant added value for the conveyance of solids and serves to ensure a very long system service life.

.