![]() Deutsche Fassung

Deutsche Fassung

SIMONA as a partner

- Close collaboration on project detailing with the end customer/processing contractor

- Technical support as early as the planning phase

- Development of a planning proposal by SIMONA

- Welding instruction and supervision on site

.

SIMOFUSE®: SIMONA PE 100 customised components with integral electrofusion joints for the renewal of a stormwater basin pumping station

The DN 800 drainage pipes (steel with a cement-mortar lining) of a stormwater retention basin were showing signs of considerable damage. Long medium dwell times had led to corrosion along the sides of the pipes. As a result, all the steel piping had to be replaced with a pipe material that would have a high level of resistance to corrosion.

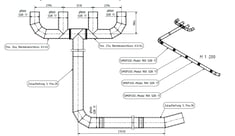

In doing so there was an important objective: to minimise construction time during which the stormwater retention basin would be out of service. Based on a detailed analysis of the existing pipes, SIMONA AG developed a planning proposal that included prefabricated assemblies, short welding times and assembly drawings.

SIMONA® pipes and fittings are ideal for the requirements described: they are characterised by inner and outer corrosion resistance, which makes expensive subsequent rehabilitation work unnecessary. In conjunction with the smart joining method SIMOFUSE® the benefits of fast, efficient assembly for push-on connections are combined with the safety of integral joining by electrofusion welding.

Furthermore, neither on the inside of the pipe nor on the outside is there any welding flash. It was possible to prefabricate entire assemblies of pipes and fittings, which simplified handling on site and shortened the total processing time. In addition to providing welding instruction and supervision on site, SIMONA AG is also available to answer any questions after completion of the project.

.